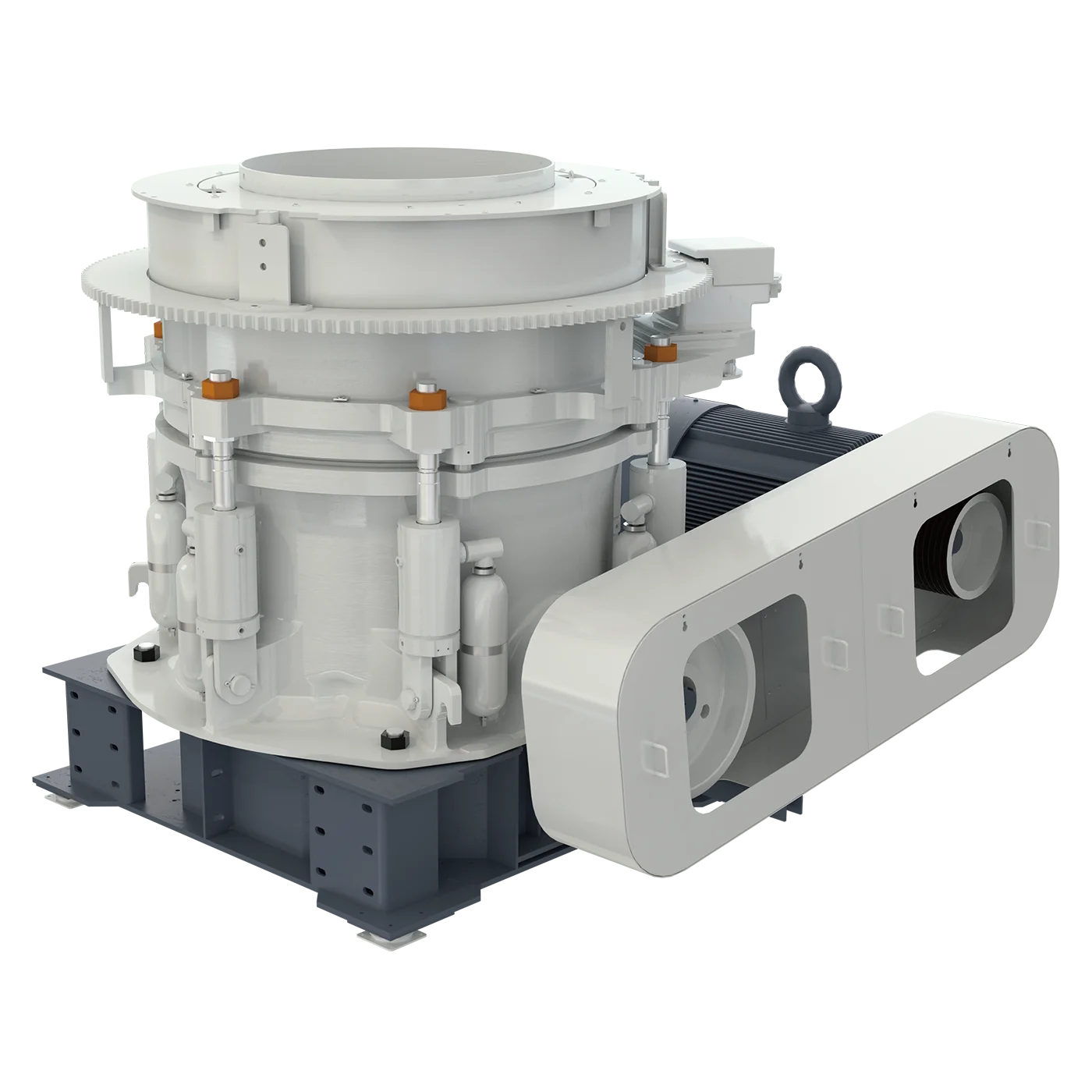

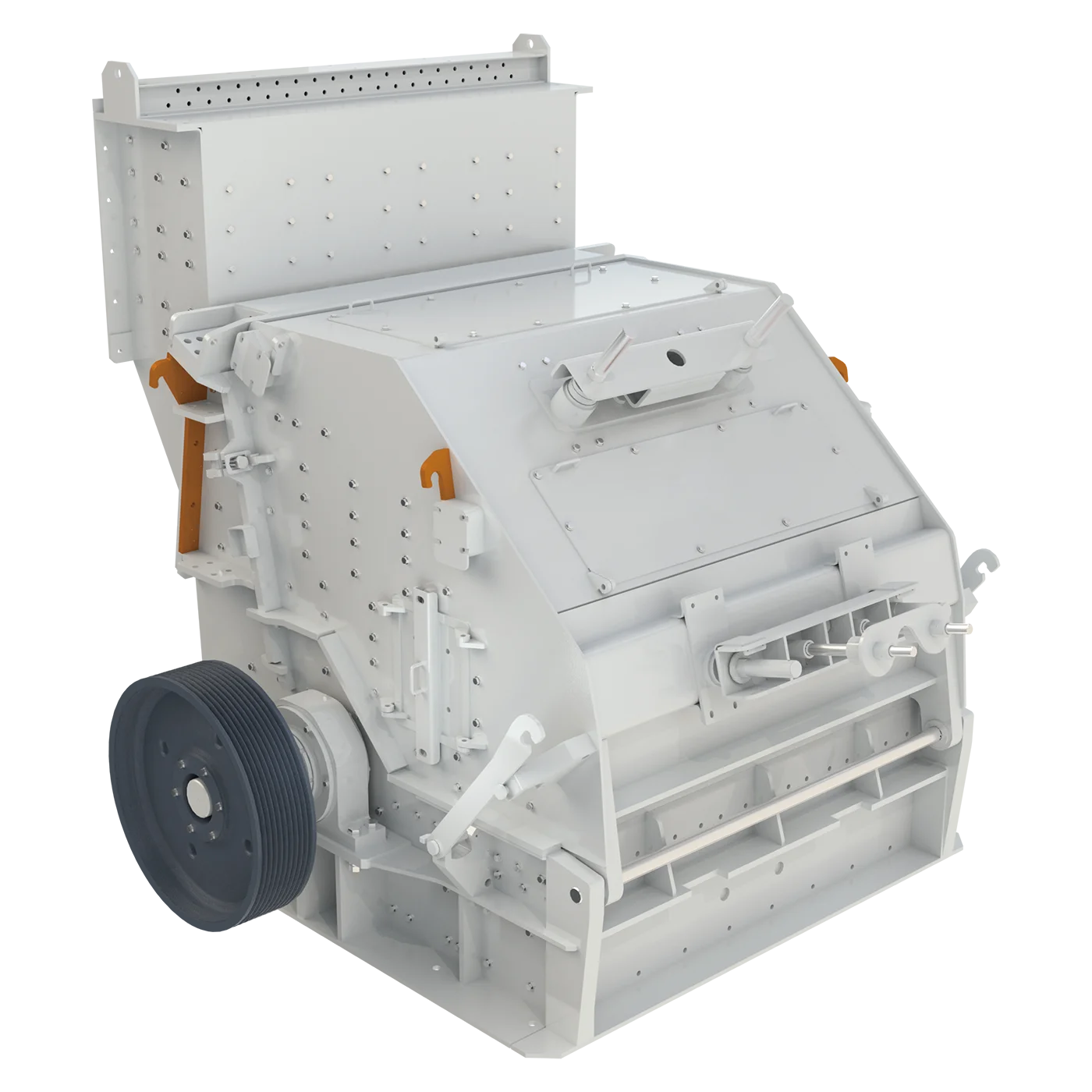

SS/SH Series Single Cylinder Hydraulic Cone Crusher

It can be used for crushing operations in mines and stone industries of various scales. SS series can be used as coarse and medium crushing, and SH series can be used as medium and fine crushing. Up to dozens of cavity shape changes and a variety of eccentricities are set for an eccentric bushing, greatly enhancing the flexibility and adaptability of the equipment.

Inquiry

- Heavy Duty Design

The structure of the frame is optimized by finite element analysis, and the main shaft is forged with high-quality alloy steel to improve the reliability of the equipment under heavy-duty conditions. - High Performance Transmission Design

Spiral bevel gears are used for large and small gears to achieve high energy efficiency and large torque transmission. The gear clearance is adjusted externally to facilitate maintenance. - Multi Eccentricity Setting

Multiple eccentricity settings can be realized by adjusting different keyway positions, which can adapt to various ore characteristics and working conditions. - Laminated Crushing Design

Optimize the cavity shape to realize the lamination crushing principle, thus improving the output and particle shape. - Design Of Integrated lubrication Hydraulic Station

The lubricating system and hydraulic system are designed in an integrated module. The oil tank is divided into two parts and operates independently. It is interlocked with the main engine to realize abnormal protection of oil temperature, oil pressure and flow.

TECHNICAL PARAMETERS

| Model | Maximum Feed Size(mm) | Motor Power(kw) | Outlet(mm) | Processing Capacity(t/h) | Equipment Weight(t) |

| SS430 | 350 | 160 | 19-54 | 100-355 | 12.5 |

| SS440 | 450 | 250 | 25-54 | 200-610 | 19.6 |

| SS550 | 450 | 315 | 25-70 | 215-670 | 29.8 |

| SS660 | 550 | 315 | 38-83 | 325-1070 | 36 |

| SH430 | 185 | 160 | 6-39 | 50-215 | 9.5 |

| SH440 | 215 | 250 | 8-44 | 90-405 | 15 |

| SH660 | 275 | 315 | 13-51 | 165-670 | 27.2 |

| SH860 | 275 | 500 | 10-51 | 175-1140 | 40.2 |

| SH870 | 300 | 630 | 10-70 | 280-1525 | 50.5 |

| SH890 | 370 | 800 | 10-70 | 185-2220 | 92.4 |

PROCESSING CAPACITY

| Model | Processing capacity (T / h) of corresponding points of different wide side discharge openings (mm) | ||||||||||||||||

| 19 | 22 | 25 | 29 | 32 | 35 | 38 | 41 | 44 | 48 | 51 | 54 | 60 | 64 | 70 | 76 | 80 | |

| SS430 | 100 | 105-135 | 110-175 | 120-230 | 130-240 | 135-305 | 145-320 | 155-340 | 160-355 | 115-315 | 210-265 | 220 | |||||

| SS440 | 200 | 220-275 | 235-350 | 245-445 | 260-495 | 275-520 | 290-575 | 310-610 | 330-535 | 370-465 | |||||||

| SS550 | 215-270 | 230-390 | 250-420 | 260-450 | 275-475 | 290-500 | 300-520 | 315-545 | 335-575 | 345-600 | 360-625 | 390-670 | 405-605 | 435-495 | |||

| SS660 | 325 | 340-430 | 360-630 | 380-765 | 400-800 | 415-865 | 450-940 | 475-990 | 510-1070 | 565-990 | 590 | ||||||

| Model | 6 | 8 | 10 | 13 | 16 | 19 | 22 | 25 | 32 | 38 | 44 | 51 | 64 | 70 | 70 |

| SH430 | 50-80 | 53-85 | 55-110 | 60-140 | 65-155 | 70-165 | 75-180 | 85-190 | 95-215 | 110-215 | |||||

| SH440 | 90-135 | 95-180 | 100-230 | 105-285 | 115-305 | 120-325 | 130-350 | 150-385 | 165-405 | 190-400 | |||||

| SH660 | 195-310 | 165-375 | 175-450 | 190-495 | 200-530 | 230-600 | 250-665 | 275-670 | 320-520 | ||||||

| SH860 | 175-425 | 190-510 | 200-680 | 215-625 | 230-670 | 245-760 | 280-845 | 310-945 | 340-1040 | 540-1140 | |||||

| SH870 | 280-415 | 310-540 | 330-680 | 355-725 | 380-795 | 405-900 | 460-1030 | 510-1135 | 555-1240 | 660-1370 | 710-1475 | 775-1525 | 825-1340 | ||

| SH890 | 185-485 | 200-595 | 215-675 | 230-850 | 245-960 | 260-1245 | 295-1420 | 325-1565 | 355-1710 | 395-1890 | 425-2040 | 475-2210 | 510-2200 |

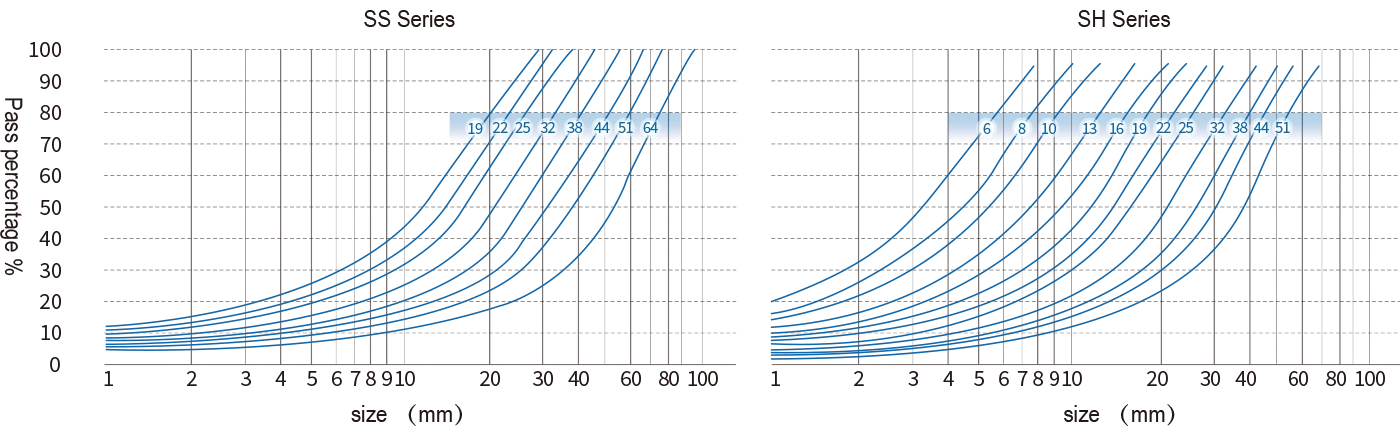

PRODUCT SIZE CURVE

Note: the above parameter are for reference only,which may change according to the actual working conditions. Please refer to Shenyang Hansy for details.