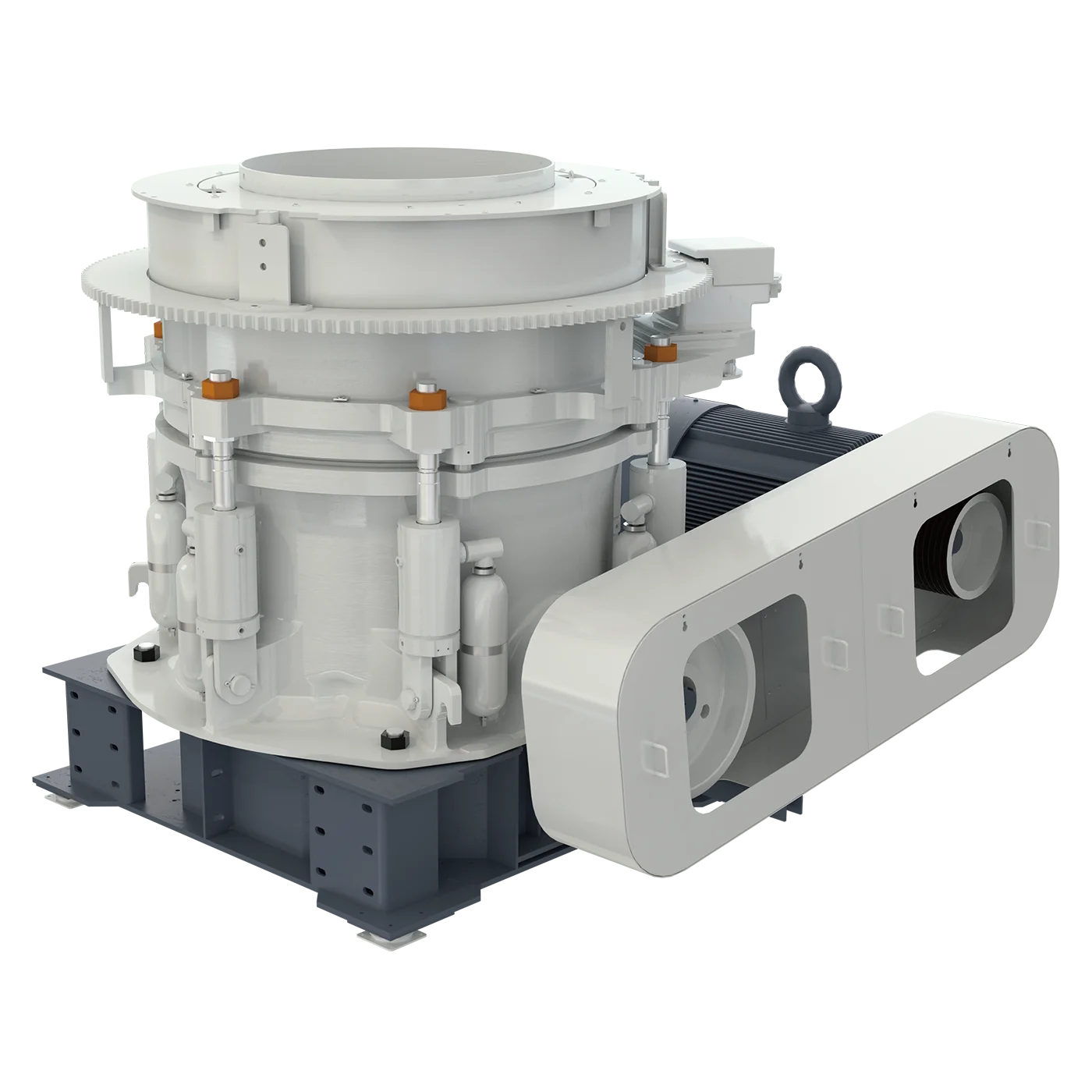

MX Series Gyratory Crushers

Mainly applied in in metal mines and aggregates industries. Generally applied for coarse crushing of various ores and rocks with the advantages of large capacity, high crushing efficiency, large crushing ratio and low energy consumption.

Inquiry

- Heavy-Duty Design

The high-strength optimization design of the upper and lower shells, and the integrated design of the main shaft and head ensures stable operation and longer service life of the equipment under bad crushing conditions. - Optimized Design Of Girder Structure

The girder cone fitting design to prevent loosening and improve reliability; equipped with automatic lubrication device for easy maintenance; Without dismantling the girder to replace bushing and sealing to increase the maintenance efficiency. - Multi-eccentricity Design

Multiple eccentric distances to meet different production conditions. - Optimized Design Of Backlash Adjustment

The gear backlash can be adjusted from the outside, which is more convenient to adjust. - Design Of Positive Pressure Sealing

Equipped with a positive pressure fan to effectively prevent dust from entering the oil cavity and prolong the service life of bearings and bushings. - Convenient Mainshaft Position Adjustment System

Equipped with a built-in mainshaft displacement sensor to monitor the mainshaft position in real time and convenient for setting the discharge port. - Modular Lubrication Hydraulic System Design

The integrated oil tank is divided into two parts. The lubrication system and the hydraulic system operate independently. The main lubrication system and the pinion lubrication system are provided with independent oil circuits, which are interlocked with the main machine to realize protection of oil temperature, oil pressure and flow rate from abnormal.

TECHNICAL PARAMETERS

| Model | Feed Port Size (mm) | Recommended Maximum Feed (mm) | Motor Power (kw) | Outlet (mm) | Processing Capacity (t/h) | Equipment Weight (t) |

| MX4265 | 1100 | 900 | 400 | 140-175 | 1480-2170 | 120 |

| MX5065 | 1300 | 1050 | 400 | 150-175 | 2090-2610 | 154 |

| MX5475 | 1400 | 1150 | 500 | 150-200 | 2400-3230 | 244 |

| MX6089 | 1500 | 1300 | 630 | 165-230 | 3950-5400 | 396 |

PROCESSING CAPACITY

| Model | Processing capacity (T/h) of corresponding points of different wide side discharge openings (mm) | |||||||

| 140 | 150 | 165 | 175 | 190 | 200 | 215 | 230 | |

| MX4265 | 1480 | 1730 | 1950 | 2170 | ||||

| MX5065 | 2090 | 2470 | 2610 | |||||

| MX5475 | 2400 | 2700 | 2870 | 3060 | 3230 | |||

| MX6089 | 3950 | 4210 | 4650 | 4850 | 5130 | 5400 | ||

Note: the above parameter are for reference only,which may change according to the actual working conditions. Please refer to Shenyang Hansy for details.