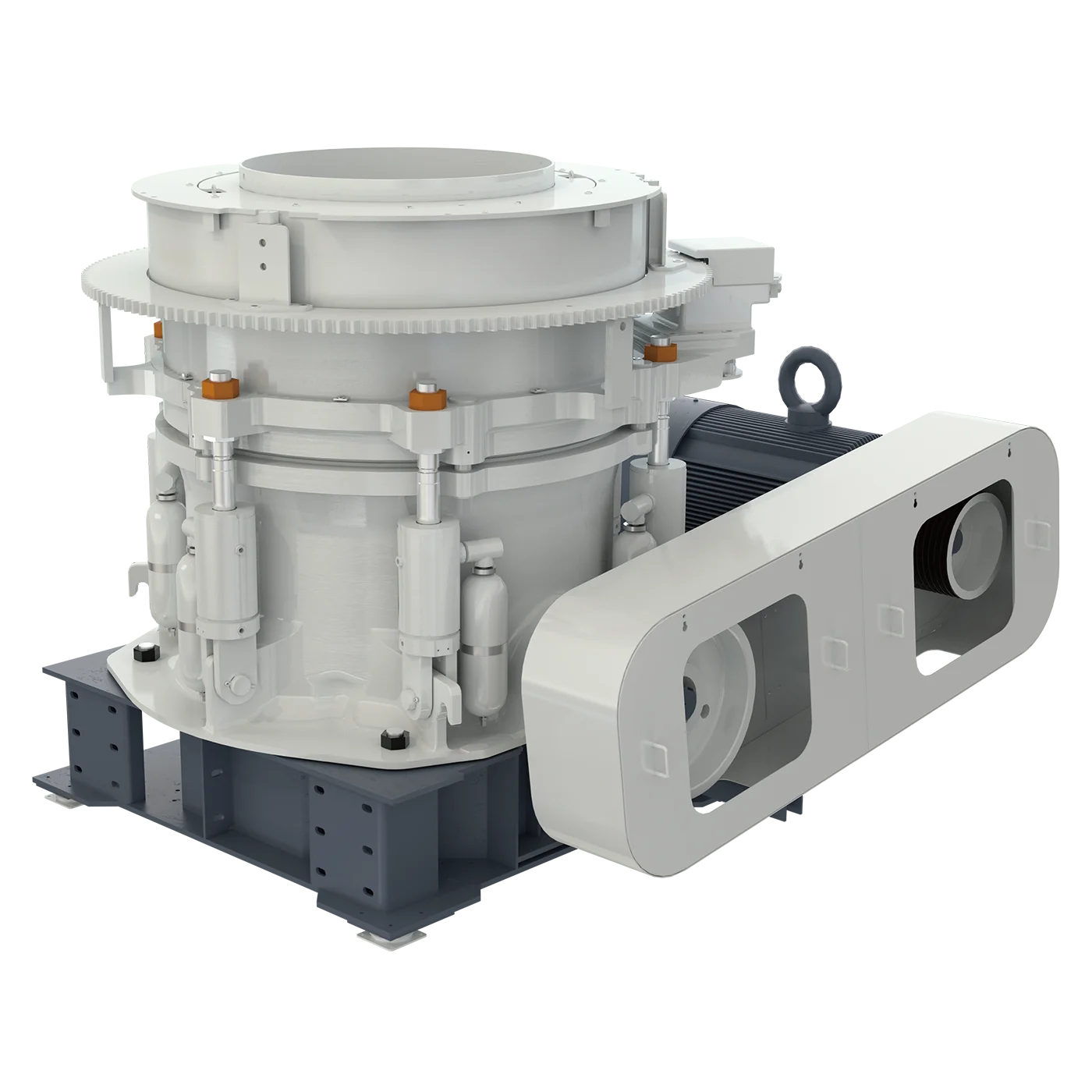

MH Series Multi-cylinder Hydraulic Cone Crusher

It is widely used in medium and fine crushing operations in mines and gravel aggregate industries. The heavy-duty working condition design enables it to have ultra-high stability, optimize the main machine structure, cooperate with large eccentricity and high speed, greatly improve the production capacity and crushing efficiency. The “laminated crushing” principle can obtain better product particle shape.

Inquiry

- Heavy Duty Design

Optimize the main frame structure, forge the main shaft with high-quality alloy steel, and improve the reliability of the equipment under heavy-duty conditions through finite element analysis. - Efficient overload protection

By replacing the lining plate, cutting ring, fastening bolt and other components, the crushing chamber can be converted from standard extra thick type to short head extra thin type. - Convenient Discharge Port Adjustment Device

The hydraulic motor drives the fixed cone to rotate, so as to accurately adjust the ore discharge port. At the same time, the fixed cone can be rotated out of the adjustment ring thread to facilitate the replacement of the lining plate. - Reliable Dust-Proof Design

Adopt “U” and “t” labyrinth seal and positive pressure fan to ensure reliable dust-proof effect. - Flexible Cavity Adjustment

By replacing the lining plate, cutting ring, fastening bolt and other components, the crushing chamber can be converted from standard extra thick type to short head extra thin type. - Comprehensive Wear Protection

All key parts of the crusher are equipped with wear-resistant protection to minimize maintenance costs.

TECHNICAL PARAMETERS

| Model | Maximum Feed Size(mm) | Motor Power(kw) | Outlet(mm) | Processing Capacity(t/h) | Equipment Weight(t) |

| MH100 | 140 | 6-32 | 90 | 50-150 | 6.5 |

| MH200 | 170 | 6-38 | 160 | 65-260 | 12.5 |

| MH300 | 240 | 8-45 | 250 | 90-450 | 18.6 |

| MH400 | 300 | 8-51 | 315 | 110-645 | 26 |

| MH500 | 310 | 8-55 | 400 | 135-800 | 37.6 |

| MH600 | 330 | 10-55 | 500 | 225-800 | 45.5 |

| MH800 | 350 | 10-60 | 630 | 265-1220 | 66.4 |

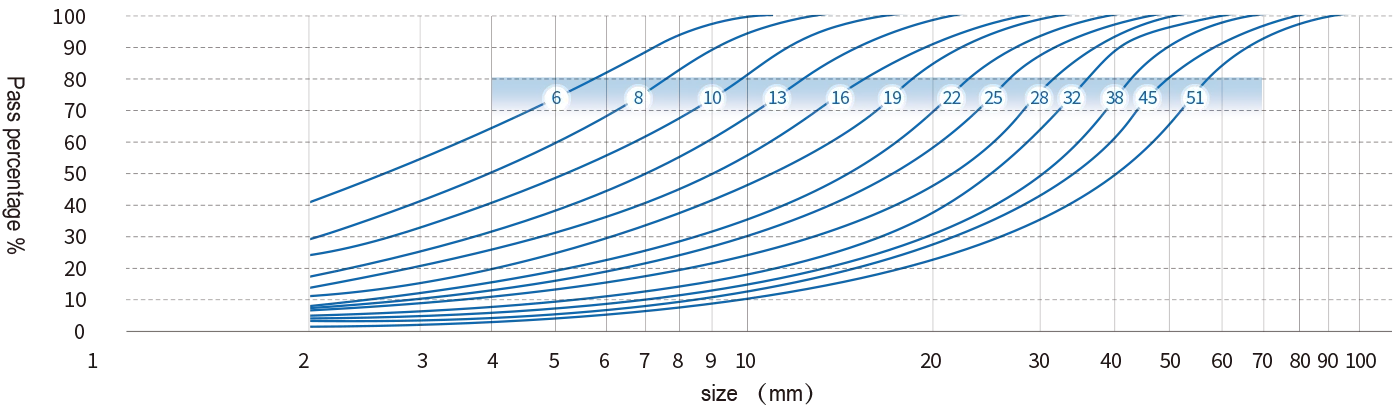

PROCESSING CAPACITY

| Model | Processing capacity (T / h) of corresponding points of different wide side discharge openings (mm) | |||||||||||

| 6 | 8 | 10 | 13 | 16 | 19 | 22 | 25 | 32 | 38 | 45 | 51 | |

| MH100 | 50-65 | 55-70 | 60-80 | 65-90 | 75-100 | 80-105 | 85-110 | 85-110 | 105-150 | |||

| MH200 | 65-85 | 75-100 | 95-130 | 125-160 | 145-190 | 155-200 | 165-210 | 165-210 | 195-245 | 215-260 | ||

| MH300 | 90-105 | 120-150 | 155-195 | 185-230 | 205-250 | 225-270 | 225-270 | 255-330 | 305-390 | 355-450 | ||

| MH400 | 110-145 | 145-180 | 190-235 | 230-285 | 260-325 | 280-355 | 280-355 | 330-440 | 365-500 | 415-570 | 470-645 | |

| MH500 | 135-150 | 180-230 | 235-300 | 285-360 | 325-410 | 350-440 | 350-440 | 410-545 | 450-615 | 515-710 | 585-800 | |

| MH600 | 225-310 | 285-390 | 340-460 | 375-500 | 415-545 | 415-545 | 445-640 | 520-725 | 575-800 | |||

| MH800 | 265-345 | 330-435 | 390-510 | 440-555 | 475-610 | 475-610 | 550-810 | 605-960 | 695-1060 | 790-1220 | ||

PRODUCT SIZE CURVE

Note: the above parameter are for reference only,which may change according to the actual working conditions. Please refer to Shenyang Hansy for details.