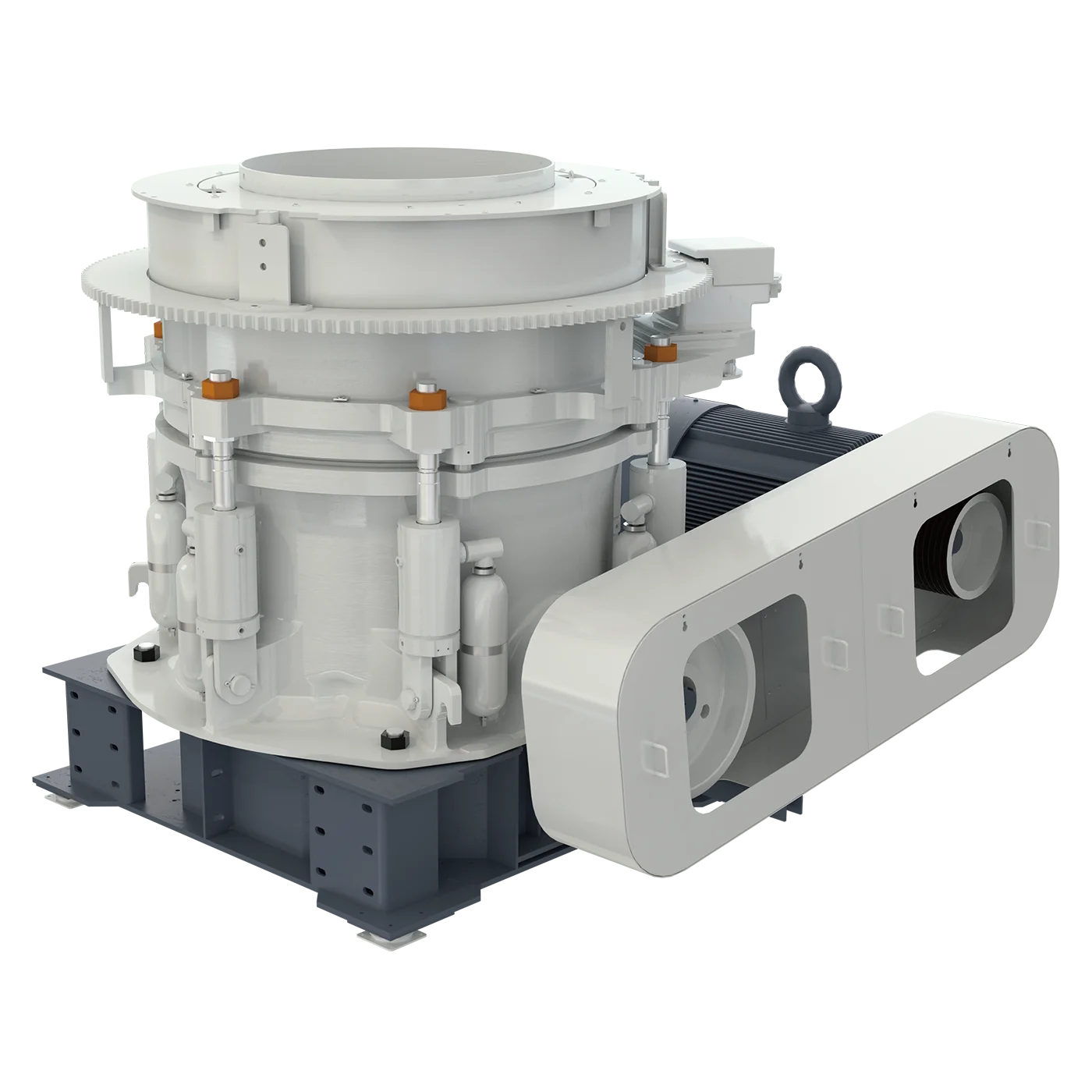

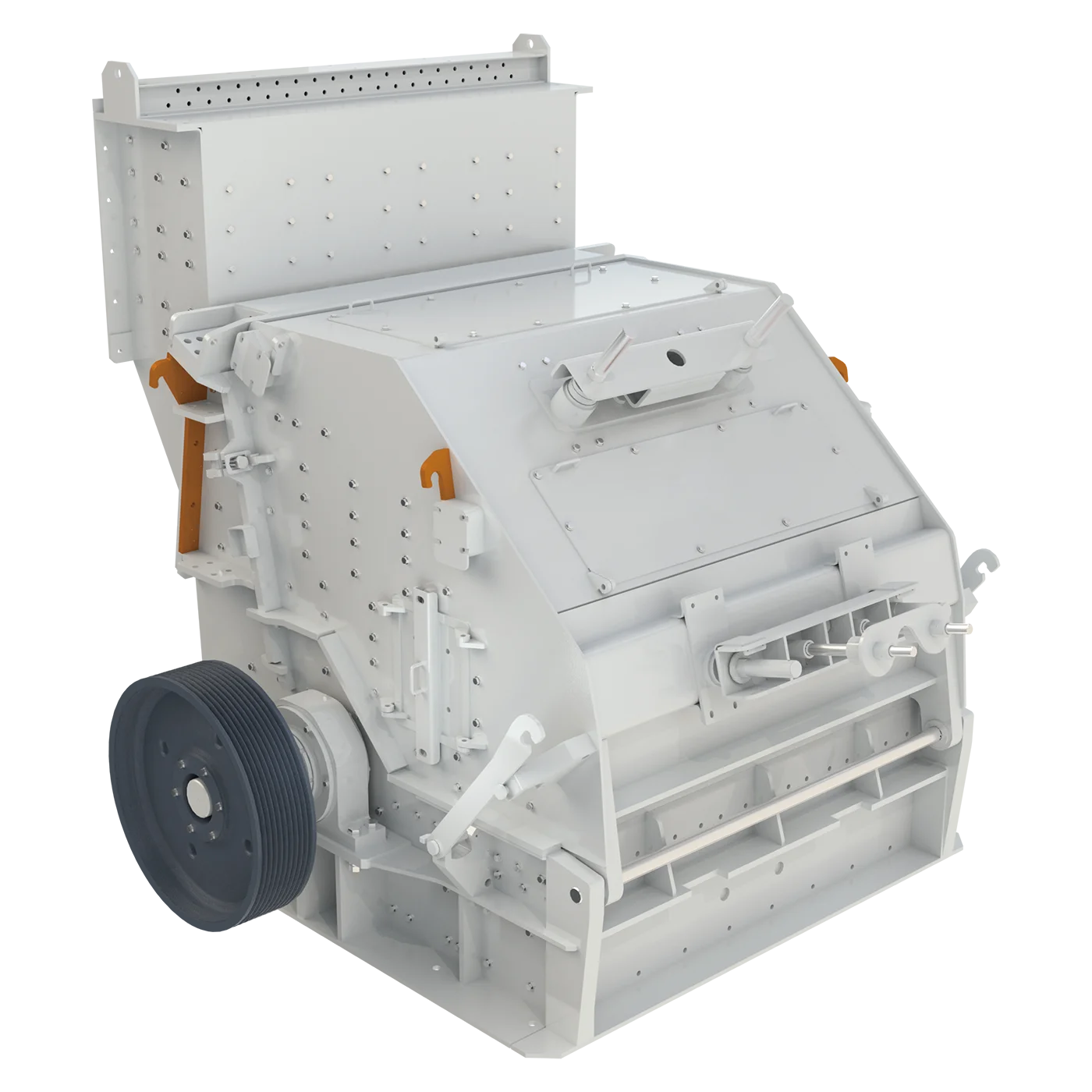

MG Series Single Cylinder Hydraulic Cone Crusher

Designed according to heavy-duty working conditions, it can be applied to crushing operations in mines and stone industries of various scales. Among them, the suffix “s” series with larger grain size can be used as coarse and medium crushing, and no suffix “s” can be used as medium and fine crushing. This series of crushers has the advantages of low cost, simple operation and wide range of use.

Inquiry

- High Reliability

The frame finite element analysis optimizes the structure and large diameter spindle design, greatly improving the reliability of the equipment. - High Performance Transmission Design

Spiral bevel gears are used for large and small gears to achieve high energy efficiency and large torque transmission. - Wide Applicability

By changing the lining plate and setting a plurality of eccentricities,It can adapt to various ore characteristics and working conditions. - Optimize The Crushing Cavity

Cavity optimization design, large feeding port, large throughput and good particle shape. - Convenient Maintenance

The equipment is simple to operate, the lining plate installation does not need packing, all parts of the crusher can be lifted from the upper part, and the vulnerable parts can be easily replaced.

TECHNICAL PARAMETERS

| Model | Maximum Feed Size(mm) | Motor Power(kw) | Outlet(mm) | Processing Capacity(t/h) | Equipment Weight(t) |

| MG100S | 210 | 90 | 20-45 | 80-250 | 7.5 |

| MG200S | 290 | 160 | 25-50 | 115-360 | 11.2 |

| MG300S | 330 | 250 | 25-50 | 175-540 | 16.5 |

| MG500S | 440 | 355 | 45-80 | 310-1060 | 33.5 |

| MG700S | 450 | 560 | 30-90 | 350-1500 | 63.5 |

| MG110 | 135 | 90 | 7-25 | 40-110 | 6 |

| MG220 | 205 | 220 | 8-35 | 70-280 | 10.5 |

| MG330 | 215 | 315 | 8-35 | 105-390 | 16 |

| MG550 | 235 | 400 | 10-45 | 140-510 | 27.2 |

PROCESSING CAPACITY

| Model | Processing capacity (T / h) of corresponding points of different wide side discharge openings (mm) | ||||||||||

| 20 | 25 | 30 | 35 | 40 | 45 | 50 | 55 | 60 | 65 | 70-90 | |

| MG100S | 80-90 | 105-130 | 120-200 | 135-240 | 150-250 | 160-235 | |||||

| MG200S | 115-150 | 145-180 | 160-290 | 185-330 | 205-360 | 235-270 | |||||

| MG300S | 175-200 | 175-280 | 195-410 | 215-510 | 240-540 | 260-360 | |||||

| MG500S | 310-360 | 335-710 | 385-760 | 410-960 | 435-1060 | 435-1060 | |||||

| MG700S | 350-450 | 430-640 | 500-840 | 580-970 | 650-1140 | 750-1260 | 830-1380 | 900-1500 | 900-1500 | ||

| Model | 6 | 8 | 10 | 15 | 20 | 25 | 30 | 35 | 40 |

| MG110 | 40-55 | 45-70 | 50-80 | 55-110 | 70-110 | ||||

| MG220 | 70-90 | 80-130 | 105-175 | 120-230 | 150-265 | 165-280 | 180-260 | ||

| MG330 | 105-145 | 110-190 | 130-260 | 155-300 | 180-350 | 210-390 | 265-360 | ||

| MG550 | 140-165 | 160-310 | 190-340 | 230-410 | 250-450 | 280-510 | 350-450 |

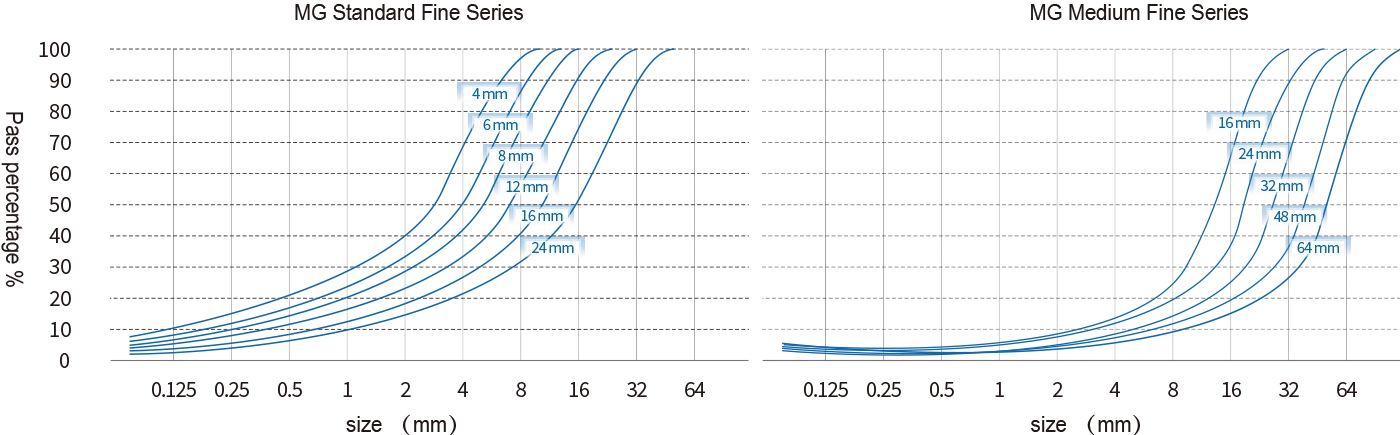

PRODUCT SIZE CURVE

Note: the above parameter are for reference only,which may change according to the actual working conditions. Please refer to Shenyang Hansy for details.