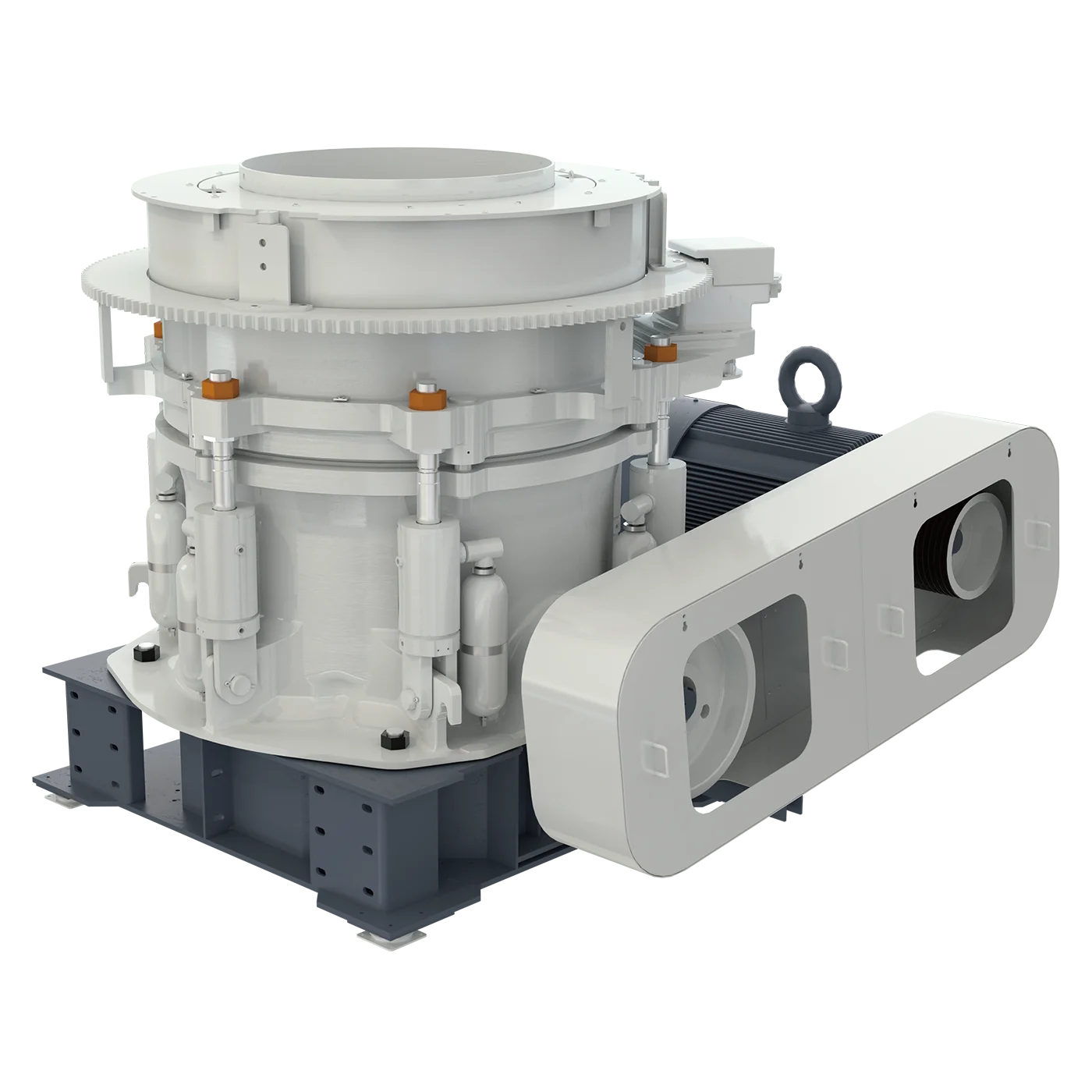

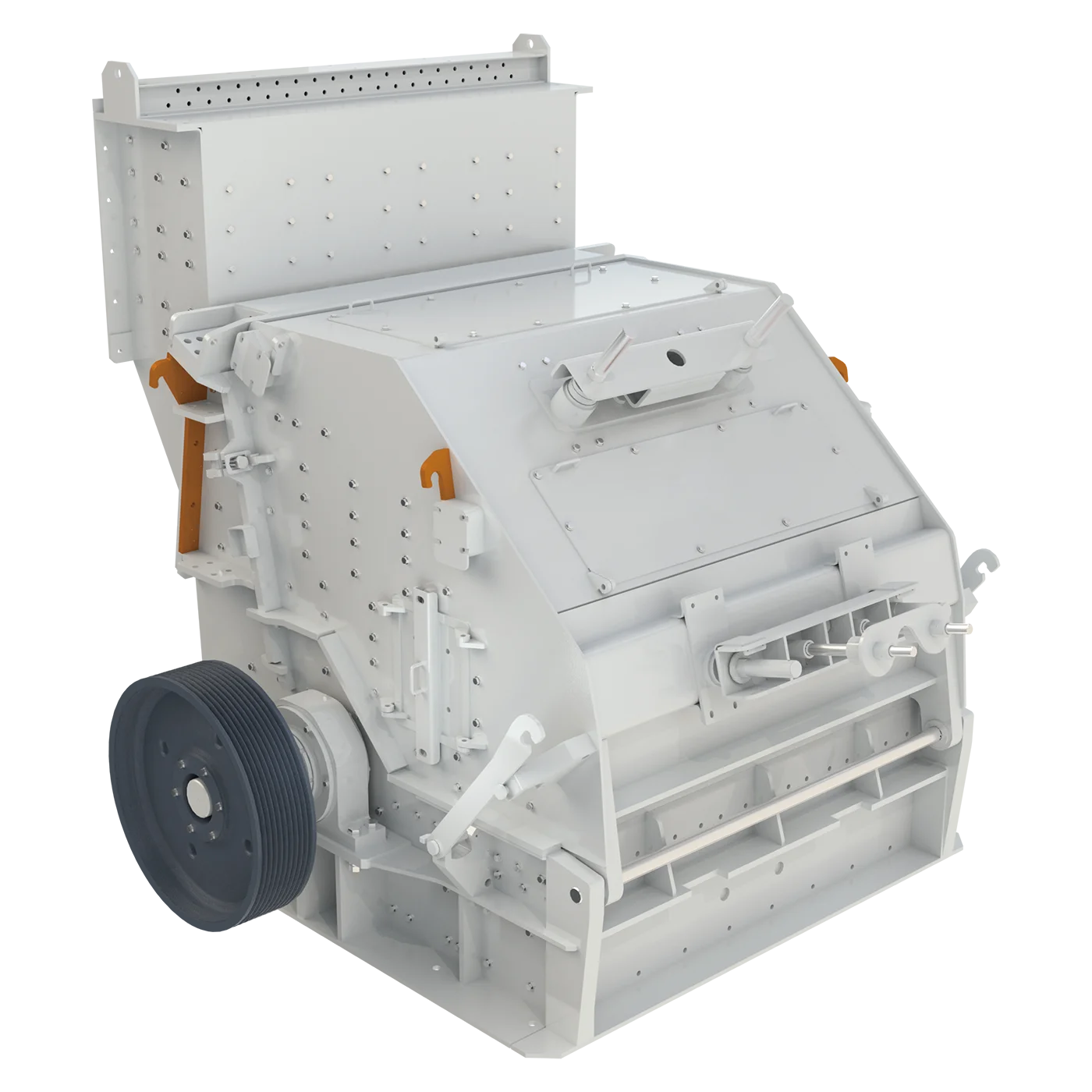

ME Series Jaw Crusher

Mainly applied in metal mines, aggregates, construction recycling, industrial slag industries. Generally applied for coarse crushing. It can be continuously fed by Hansy HGL series feeder, which has the advantages of large processing capacity, convenient installation and simple maintenance.

Inquiry

- Installation Without Anchor Bolts

The machine installation doesn’t need anchor bolts, which adopts the shock-absorbing pad and the limit block for fixing. The good balance design ensures the smooth operation of the machine. - Frame Body Without Welding Design

The frame body adopts a non-welding modular design to avoid the reduction of service life due to stress concentration when to withstand impact load. - Integrated Design Of Motor

The drive motor is installed on the crusher without the separate installation foundation. The overall equipment is more compact, and the installation is simpler and more convenient. - Double Wedge Outlet Adjustment Design

Equipped with double wedge hydraulic adjustment system, outlet adjustment, fast and lightweight, two configurations are available, i.e. mechanical adjustment and hydraulic adjustment - Special Design For Dynamic Overload Protection System

For the special crushing requirements of steel slag, construction recycling and other industries, a dynamic overload protection system can be installed. When the unbreakable material such as steel block, enters into the crushing cavity, it will automatically resume normal operation after unloading and being discharged through the unloading and buffer device to meet the overload protection requirements.

TECHNICAL PARAMETERS

| Model | Feed Port Size(mm) | Maximum Feed Size(mm) | Motor Power(kw) | Outlet(mm) | Processing Capacity(t/h) | Equipment Weight(t) |

| ME80 | 800×510 | 420 | 75 | 40-175 | 65-365 | 9.5 |

| ME96 | 930×580 | 480 | 90 | 60-175 | 120-410 | 12.2 |

| ME100 | 1000×760 | 630 | 110 | 70-200 | 140-510 | 23.5 |

| ME106 | 1060×700 | 580 | 110 | 70-200 | 165-520 | 18.6 |

| ME116 | 1150×760 | 650 | 132 | 70-200 | 180-540 | 22.3 |

| ME120 | 1200×870 | 700 | 160 | 70-175 | 190-560 | 31.5 |

| ME125 | 1250×950 | 760 | 160 | 100-250 | 260-775 | 44 |

| ME130 | 1300×1000 | 800 | 185 | 100-250 | 285-850 | 45.8 |

| ME140 | 1400×1070 | 860 | 200 | 125-250 | 345-870 | 54.2 |

| ME150 | 1400×1200 | 1000 | 220 | 125-250 | 355-900 | 61 |

| ME160 | 1600×1200 | 1000 | 250 | 150-300 | 445-1170 | 88.2 |

| ME200 | 2000×1500 | 1200 | 400 | 175-300 | 645-1460 | 137 |

PROCESSING CAPACITY

| Model | Processing capacity of corresponding points of different discharge ports (mm) (T / h) | ||||||||||||||

| 40 | 50 | 60 | 70 | 80 | 90 | 100 | 125 | 150 | 175 | 200 | 225 | 250 | 275 | 300 | |

| ME80 | 65-90 | 75-110 | 95-130 | 110-150 | 120-160 | 140-195 | 150-210 | 190-270 | 225-310 | 260-365 | |||||

| ME96 | 120-145 | 140-165 | 150-190 | 170-220 | 190-250 | 240-300 | 280-350 | 320-410 | |||||||

| ME100 | 140-195 | 160-220 | 175-240 | 195-270 | 235-330 | 280-385 | 325-450 | 370-510 | |||||||

| ME106 | 165-200 | 180-230 | 200-250 | 220-285 | 270-350 | 320-400 | 370-470 | 410-520 | |||||||

| ME116 | 180-225 | 195-255 | 220-275 | 240-305 | 285-365 | 335-425 | 385-485 | 425-540 | |||||||

| ME120 | 190-260 | 110-290 | 225-305 | 235-325 | 300-415 | 355-495 | 400-560 | ||||||||

| ME125 | 260-355 | 310-425 | 360-495 | 410-565 | 460-635 | 510-705 | 560-775 | ||||||||

| ME130 | 285-390 | 340-465 | 395-545 | 450-620 | 505-695 | 560-775 | 615-850 | ||||||||

| ME140 | 345-475 | 400-560 | 455-635 | 515-715 | 570-790 | 630-870 | |||||||||

| ME150 | 355-490 | 415-575 | 475-655 | 535-740 | 595-820 | 655-900 | |||||||||

| ME160 | 445-630 | 510-715 | 575-810 | 640-900 | 700-985 | 760-1080 | 830-1170 | ||||||||

| ME200 | 645-910 | 725-1020 | 800-1125 | 880-1235 | 955-1340 | 1030-1460 | |||||||||

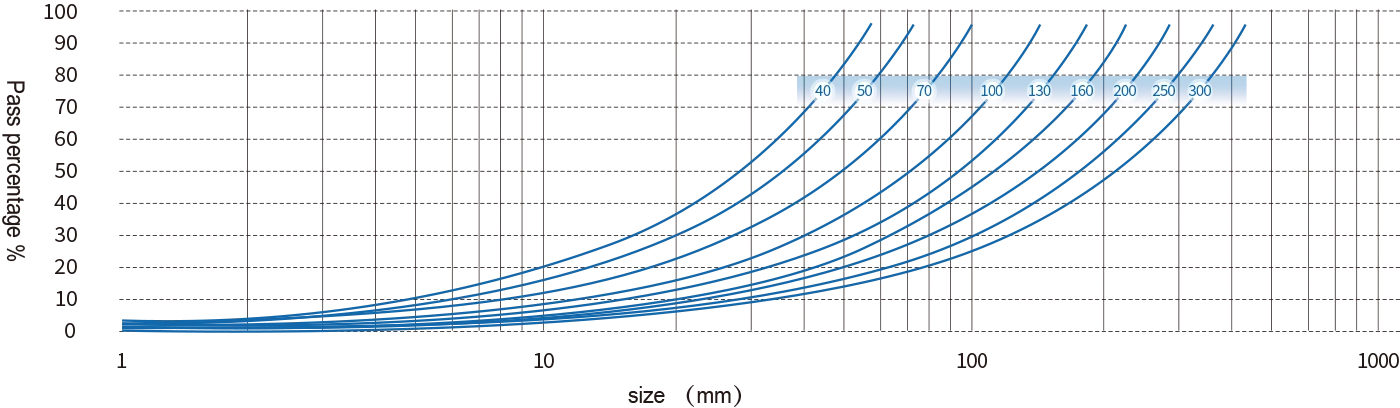

PRODUCT SIZE CURVE

Note: the above parameter are for reference only,which may change according to the actual working conditions. Please refer to Shenyang Hansy for details.