The first green environmental protection , ester hardening water-glass sand process, automatic boxless styling molding production line in China.

Using “5G + Industrial Internet”, the quality, production, cost and sales are integrated management through the MES system

Production Line

Automatic molding production line

Ester hardened water glass reduces organic emissions, ceramsite reduces solid waste emissions, unboxing reduces site occupation, and the entire molding production line achieves green and intelligent manufacturing.

Melting production line

5T medium frequency furnace melting, intelligent batching system, achieving precise batching and automatic feeding.

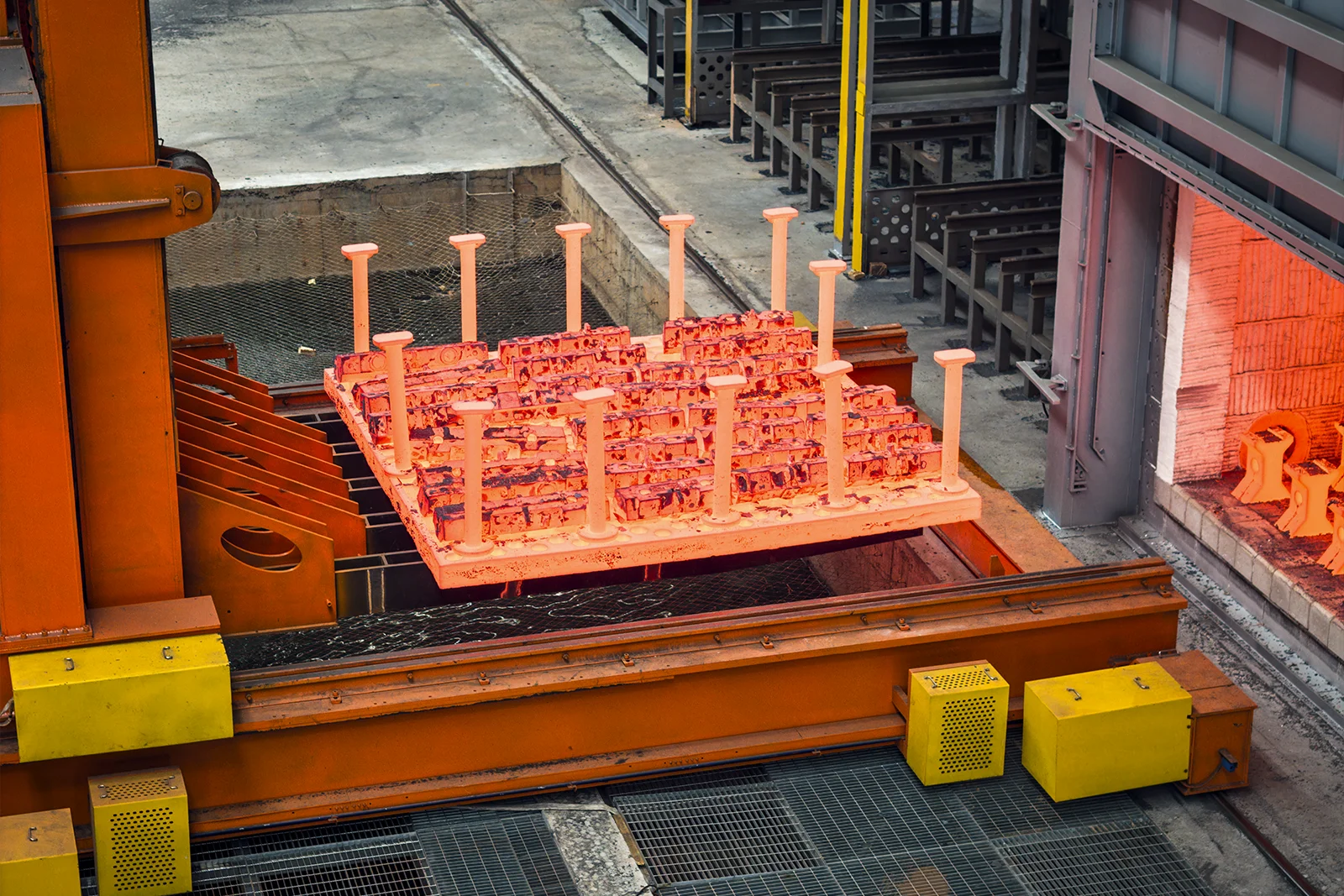

Pouring production line

The automatic transfer pouring system and the automatic transfer unpacking cooling system are used to control the pouring temperature and holding time.

Heat Treatment production line

The heat treatment production line is equipped with 3 chamber type gas heat treatment furnaces and 1 30T heat treatment operator.