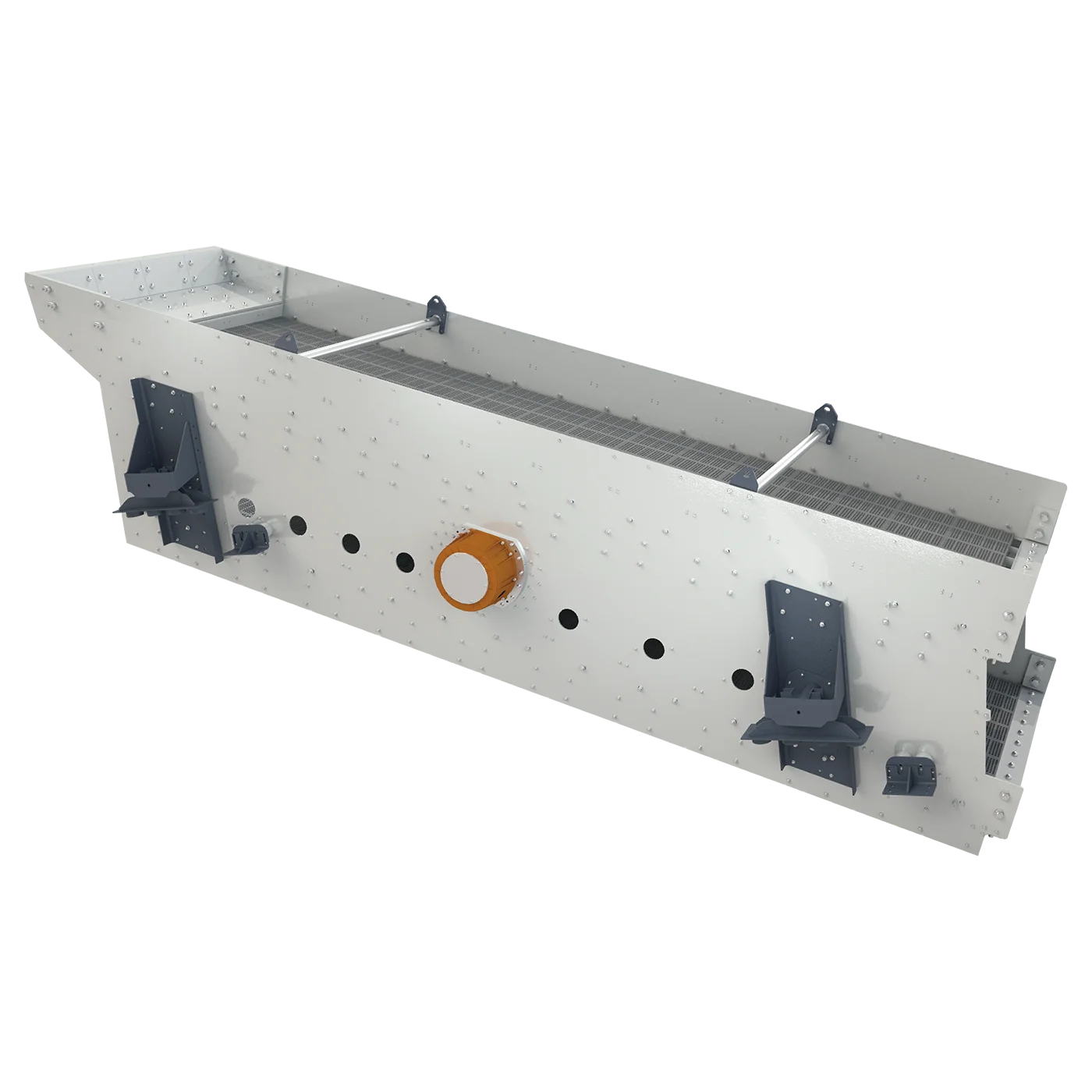

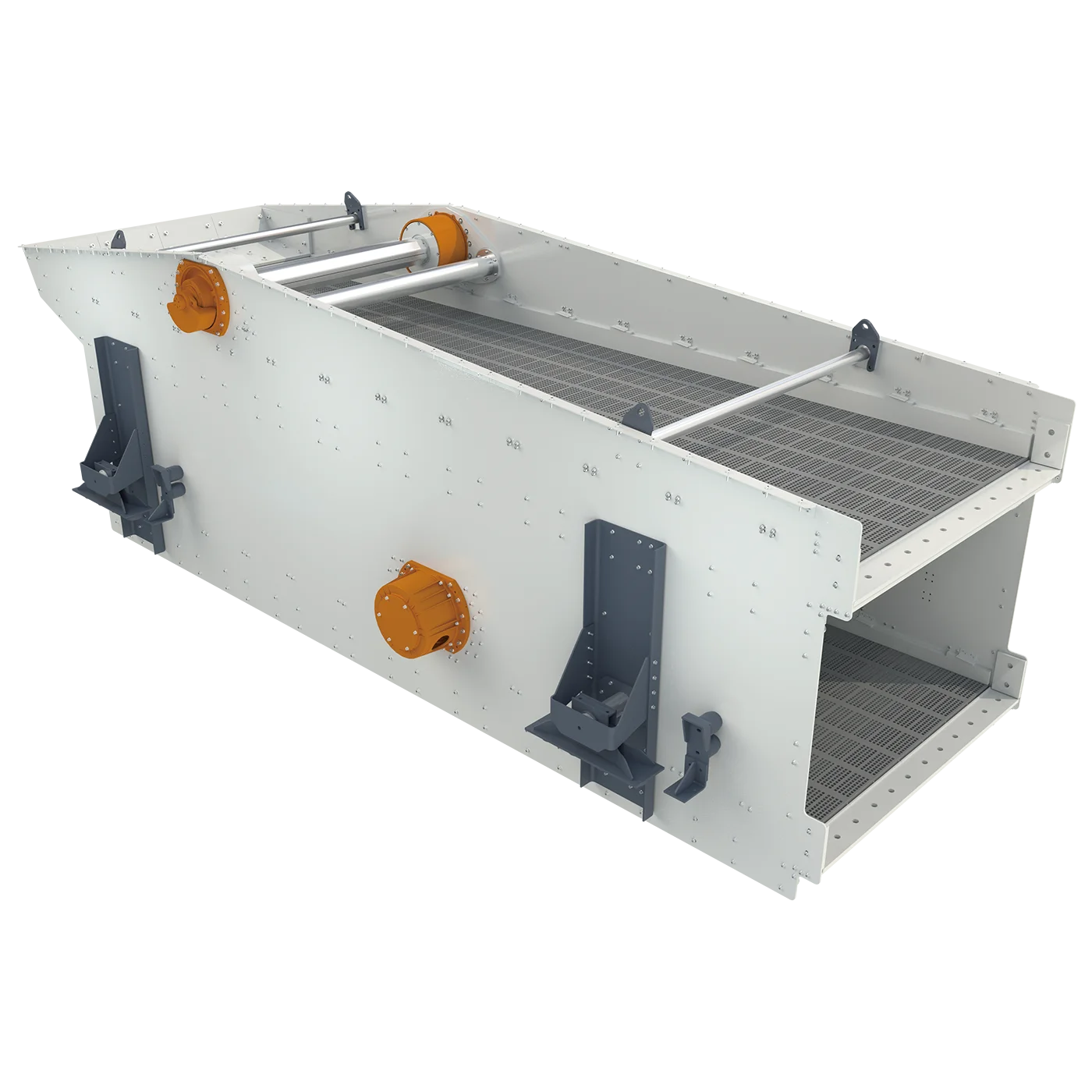

HLS Series Horizontal Screen

It is widely used in gravel aggregate, mining,chemical and building materials industries.It is especially suitable for the screening of finished materials, and can effectively eliminate the blockage of screen holes caused by viscous or sheet materials. Horizontal installation, low equipment installation height, small occupied space and stable operation.

Inquiry

- Design Of Gear Synchronous Three Shaft System

Gear synchronous three-axis arrangement, elliptical motion track, high screening efficiency and stable operation. - Optimal Design Of Excitation Force

The ratio of the long and short axes of the ellipse is 3:1, and the exciting force is strong. It can effectively improve the problem of viscous materials easily blocked in the traditional horizontal screen. The amplitude is adjustable, and can be adjusted according to the screening requirements of different materials. - Long Service Life

The screen box and the beam are riveted with high-strength rivets, without welding. Finite element analysis greatly improves the service life of the vibrating screen. - Simple Maintenance

Dry oil lubrication, modular design of exciter, simple maintenance

TECHNICAL PARAMETERS

| Model | Long × Width (m) | Sieving area ( ㎡ ) |

Number of Layers | Power (kw) | Maximum Processing Capacity(t/h) |

Maximum Feeding Particle Size (mm) |

Equipment Weight (T) |

| HLS1961-2 | 1.9×6.1 | 11.6 | 2 | 37 | 500 | 200 | 9.5 |

| HLS1961-3 | 3 | 45 | 500 | 200 | 11 | ||

| HLS2261-2 | 2.2×6.1 | 13.4 | 2 | 45 | 650 | 200 | 12.5 |

| HLS2261-3 | 3 | 55 | 650 | 200 | 13.8 | ||

| HLS2561-2 | 2.5×6.1 | 15.3 | 2 | 55 | 800 | 200 | 13.2 |

| HLS2561-3 | 3 | 55 | 800 | 200 | 15 |

Note: the above parameter are for reference only,which may change according to the actual working conditions.