Quality Control

- ISO9001 Quality System

- FEA simulations 、EDME、MillTarj、Casting-CAE and other computer-aided design professional software are applied, according customer need and special working condition to develop and design products to ensure the advanced, reliable and applicability of the products

- The MES information integrated management system is used to monitor and control the manufacturing process to ensure the manufacturing quality of the products

- The professional on-site service technical team solves the problems of products and customer concerns in a timely manner

- Equipped with the Green Environmental protection manufacturing technology, high efficiency and energy-saving product, customer-focused service system and perfect product quality, abide by corporate social responsibility

Main Inspection Equipment

Supporting rapid analysis of chemical composition, sand analysis, metallographic analysis, mechanical properties analysis and other related laboratories analysis

Metallographic

laboratory

Metallographic cutting machine

Sand molding

laboratory

Sand strength tester

Chemical Analysis

Laboratory

Direct reading spectrometer

Mechanical Properties

Laboratory

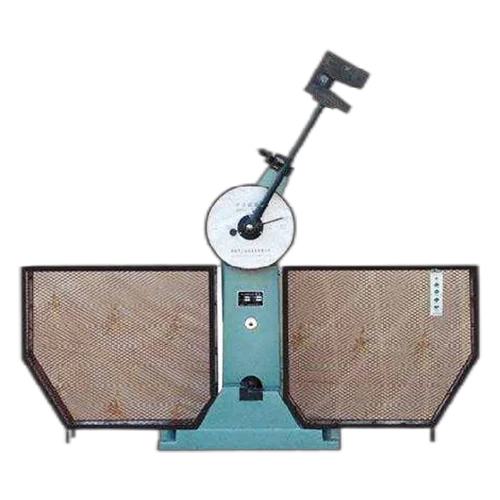

Metal material impact testing machine

Metallographic

laboratory

Metallographic microscope

Sand molding

laboratory

Sand mold permeability tester

Chemical Analysis

Laboratory

Sulfur analyzer

Mechanical Properties

Laboratory